Aletheia Spatial Targets

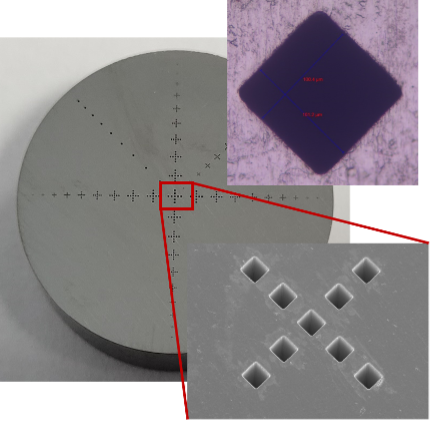

Aletheia’s 3D calibration targets make use of a patented system of feature clusters to enable instrument spatial resolution and measurement confidence to be determined in 3D reconstructed volume. Aletheia employs the most advanced manufacturing routines to fabricate its devices and can produce features as small as one micron in size.

Aletheia collaborates with the National Physical Laboratory (NPL) to provide precise feature characterisation of its 3D calibration targets, ensuring dimensional traceability can be achieved in all measurements.

IQIs

Aletheia’s 3D calibration targets are engineered to function as image quality indicators for optimising X-ray CT systems. IQIs are essential tools for enabling intersystem comparisons and for assessing instrument consistency in X-ray CT.

RQIs

For complete confidence in X-ray CT as an NDE tool, the geometry and material composition of the scanned component must be matched to the chosen 3D calibration target. Where these criteria are fulfilled, the target is said to serve as a representative quality indicator (RQI). Aletheia’s sophisticated manufacturing methods enable the production of RQIs to match a wide variety of engineering components. Aletheia can produce RQIs from all common engineering materials, including aluminium, ceramics, copper, Inconel, glass, nickel, plastics, steel, titanium and tungsten. With Aletheia’s RQIs, users of X-ray CT have the confidence that the component-specific spatial resolution is accurate to detect critical defects.